Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

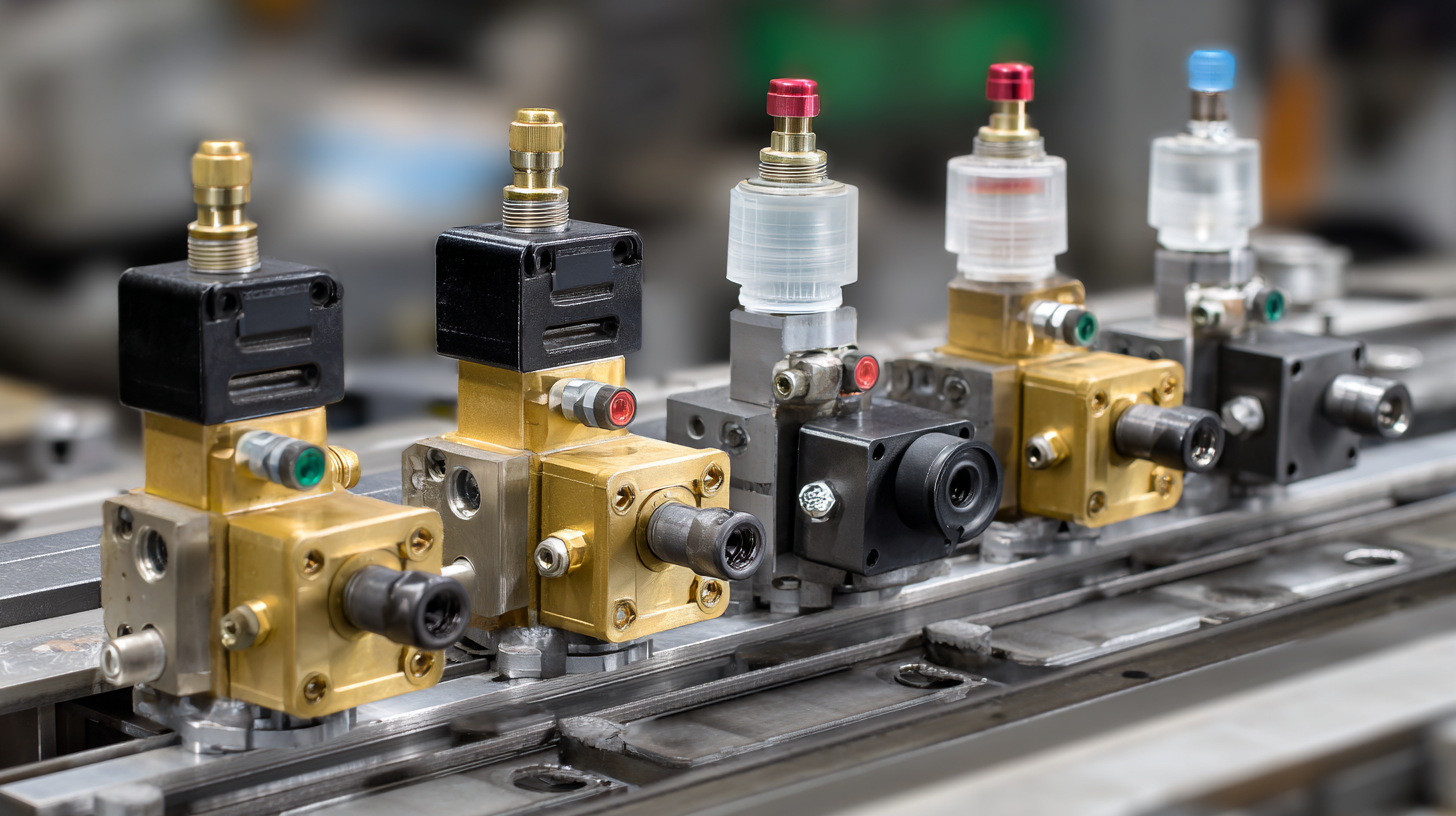

In the realm of industrial automation, the pneumatic solenoid valve stands out as a vital component that drives efficiency and precision in various applications. These valves are designed to control the flow of compressed air or gases, making them indispensable in a wide range of automated processes.

As industries increasingly seek to optimize operations and enhance productivity, understanding the technical specifications of pneumatic solenoid valves becomes crucial. This blog will explore the top 10 applications of the best pneumatic solenoid valves, highlighting their importance in streamlining workflows and improving system reliability.

Whether you’re looking to integrate these valves into your current setup or evaluate their efficacy in different roles, this comprehensive guide will not only detail the key technical parameters but also provide actionable insights on how to effectively implement and utilize pneumatic solenoid valves in your operations.

Importance of Pneumatic Solenoid Valves in Industrial Automation

Pneumatic solenoid valves play a crucial role in industrial automation, serving as the lifeblood of fluid control systems. According to a report by MarketsandMarkets, the global industrial automation market is expected to reach $298 billion by 2023, with pneumatic systems being a significant contributor due to their ability to enhance efficiency and precision. These valves regulate airflow in various applications, from assembly lines to packaging operations, ensuring that machines operate smoothly and effectively.

Tips for maximizing performance include regular maintenance of solenoid valves and choosing the right model for specific applications. It’s essential to consider the operating pressure and flow requirements; for example, selecting solenoids designed for higher pressures can prevent failures in demanding environments. Additionally, incorporating advanced sensors with pneumatic solenoid valves enhances real-time monitoring, facilitating more precise control and ensuring reliability in automated processes.

In the ever-evolving landscape of industrial automation, the adoption of smart technologies is on the rise. A study by Research and Markets indicated that the integration of IoT with pneumatic systems can improve operational efficiency by up to 30%. Choosing solenoid valves that support these technologies can future-proof your automation processes and ensure optimal performance over time.

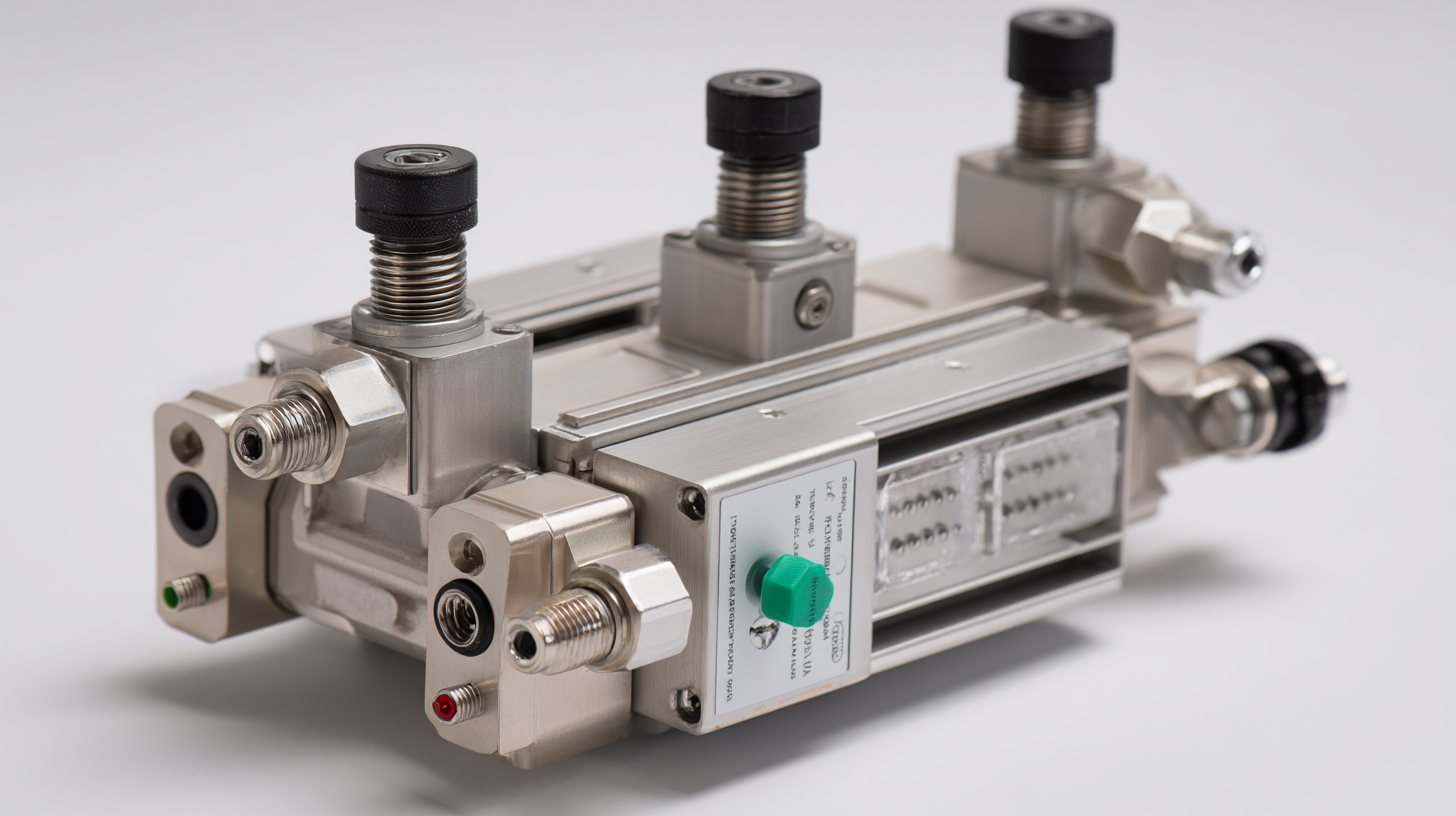

Key Features to Consider When Choosing Pneumatic Solenoid Valves

When selecting the right pneumatic solenoid valves for industrial automation, several key features must be taken into consideration. One primary aspect is the valve's response time. Faster response times are crucial in applications requiring quick actuation and precision. Additionally, ensure that the valve has a suitable operating pressure range for your specific system. This will help maintain efficiency and avoid equipment failures.

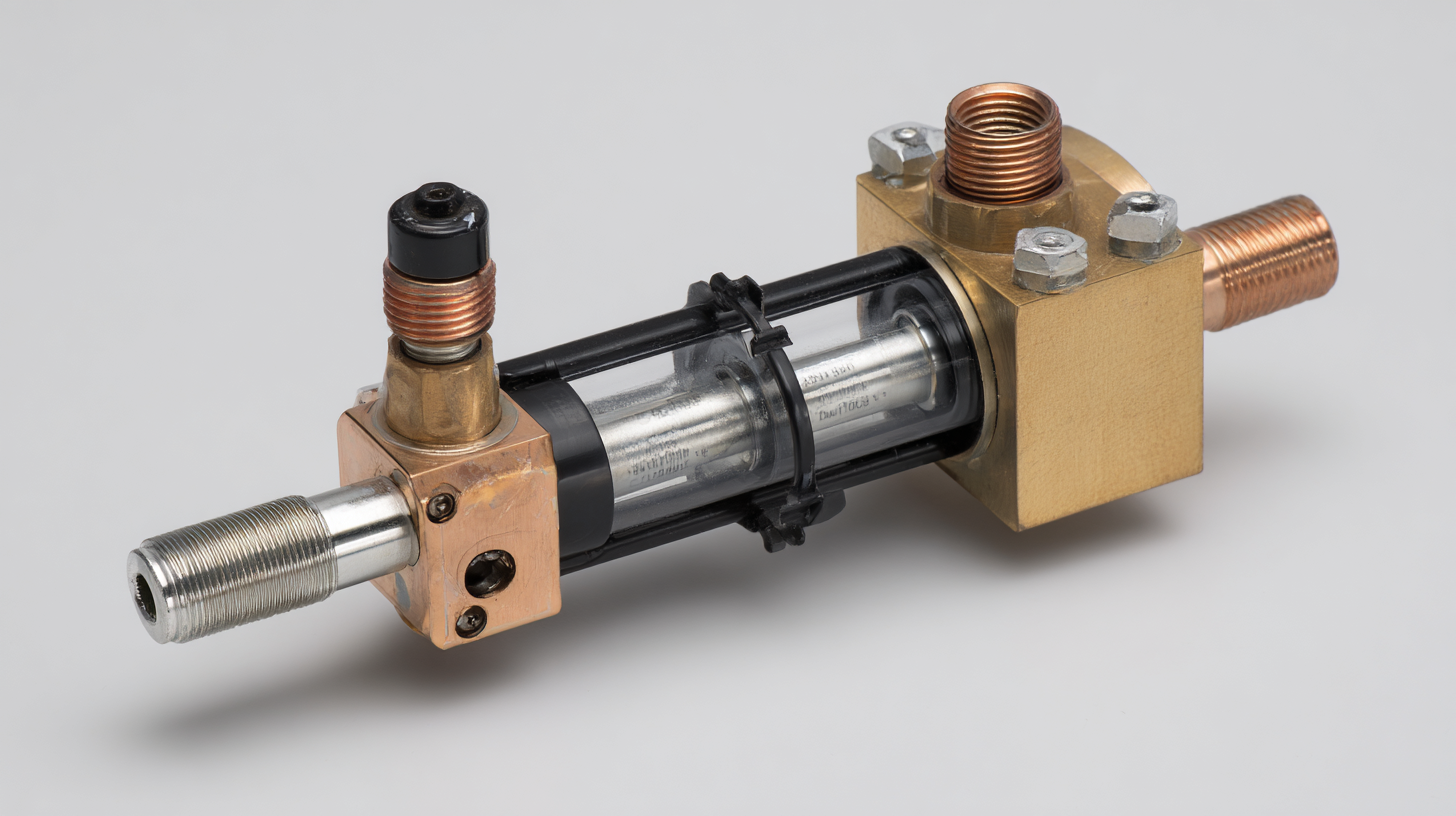

Another critical factor to consider is the valve's construction materials. The materials affect not only durability but also compatibility with the fluids being controlled. For industries handling corrosive substances, choosing valves made from robust materials like stainless steel or specialized plastics is advisable. Also, consider the sealing mechanism of the valve to prevent leaks, as this can significantly impact operational safety and costs.

Tip: Always consult manufacturer specifications for compatibility and performance ratings. Regular maintenance and inspection can also prolong the lifespan of solenoid valves, thus enhancing overall system performance. Prioritize valves from reputable brands to ensure reliability and support in case of issues.

Top Industries Utilizing Pneumatic Solenoid Valves for Efficiency

Pneumatic solenoid valves are crucial components in various industries, driving efficiency and automating processes. With the global solenoid valve market projected to reach USD 4.91 billion by 2025, the increasing demand highlights their importance in today's automated landscape. Industries such as manufacturing, automotive, and food processing extensively utilize these valves to optimize operations and ensure precision control.

One of the key sectors leveraging pneumatic solenoid valves is the HVAC industry. There is a rising demand for intelligent and IoT-integrated valves that not only enhance performance but also enable real-time monitoring and data collection. The HVAC valve market is expanding, reflecting the industry's shift towards smarter solutions. Additionally, the pneumatic actuators market, estimated at USD 51.71 billion in 2023, is expected to grow at a CAGR of 5.2% from 2024 to 2030, showcasing the synergy between actuators and solenoid valves in automation.

**Tips**: When selecting pneumatic solenoid valves, consider factors such as compatibility with existing systems and the specific requirements of your application. Regular maintenance is also essential to ensure optimal performance and longevity. Investing in high-quality valves can lead to significant cost savings and increased operational efficiency over time.

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation - Top Industries Utilizing Pneumatic Solenoid Valves for Efficiency

| Application | Industry | Efficiency Improvement (%) | Key Benefits |

|---|---|---|---|

| Automated Material Handling | Manufacturing | 20 | Reduced labor costs, improved throughput |

| Packaging and Sealing | Food and Beverage | 15 | Increased product safety, faster production |

| Fluid Control Systems | Chemical Processing | 25 | Enhanced precision, reduced waste |

| HVAC Control | Construction | 10 | Improved energy efficiency, comfort |

| Textile Machinery | Textile Industry | 30 | Higher speed, better quality |

| Robotic Arms Activation | Automation | 22 | Increased flexibility and control |

| Spraying and Coating | Manufacturing | 18 | Improved finish quality, reduced overspray |

| Leak Test Systems | Aerospace | 28 | Enhanced safety, cost reduction |

| Pressure Control | Oil and Gas | 15 | Stability in operations, safety |

| Automated Testing | Electronics | 26 | Improved accuracy, faster cycles |

Innovative Applications: Real-World Examples of Solenoid Valve Implementation

Pneumatic solenoid valves play a crucial role in the realm of industrial automation, showcasing their innovative applications across various sectors. A recent report from Transparency Market Research indicates that the global solenoid valve market is expected to reach $6 billion by 2027, driven largely by advancements in automation technologies. These valves are increasingly utilized in automated assembly lines, where precision control of airflow ensures optimal performance. For instance, in automotive manufacturing, solenoid valves are employed to control pneumatic actuators that operate robotic arms, enhancing production speed and accuracy.

In the food and beverage industry, solenoid valves facilitate the safe and efficient dispensing of liquids in processing plants. According to a study by Grand View Research, the demand for automated systems in this sector is projected to grow at a CAGR of 8% from 2021 to 2028. By integrating solenoid valves in filling machines, manufacturers can maintain stringent hygiene standards while minimizing waste during operations.

These real-world implementations underscore the versatility and reliability of pneumatic solenoid valves, cementing their place as indispensable components in modern industrial automation ecosystems.

Future Trends in Pneumatic Technology and Automation Integration

As industries continue to evolve, the future of pneumatic technology and its seamless integration with automation systems is becoming increasingly vital. One of the key trends is the growing deployment of smart pneumatic solenoid valves equipped with IoT capabilities. These advanced valves not only enhance performance through real-time data measurement but also allow for predictive maintenance, significantly reducing downtime and operational costs.

Another trend is the emphasis on energy efficiency in pneumatic systems. Innovative designs focus on minimizing air consumption without compromising performance. Industries are implementing these solutions to adhere to environmental guidelines and operational budget constraints. Automation systems that can intelligently control solenoid valves help optimize airflow and energy usage, paving the way for more sustainable operations.

**Tip:** When selecting pneumatic solenoid valves for your automation projects, consider options with built-in diagnostics to gain insights into system performance and detect potential issues before they escalate.

**Tip:** Integrate energy monitoring technologies with your pneumatic systems to identify usage patterns and implement strategies that enhance efficiency.