Ultimate Guide to Sourcing the Best Pressure Control Valves for Your Needs

In the ever-evolving world of fluid dynamics, the significance of pressure control valves cannot be overstated. These essential components play a pivotal role in regulating flow and pressure within various systems, ensuring optimal performance and safety. Whether you are an engineer seeking to enhance system efficiency or a technician tasked with maintenance, understanding how to source the best pressure control valve for your specific needs is crucial.

This ultimate guide aims to provide you with comprehensive insights into the different types of pressure control valves available, factors to consider during selection, and tips to make informed purchasing decisions. By the end of this guide, you will be equipped with the knowledge to choose the right valve that meets your operational requirements while optimizing performance and reliability.

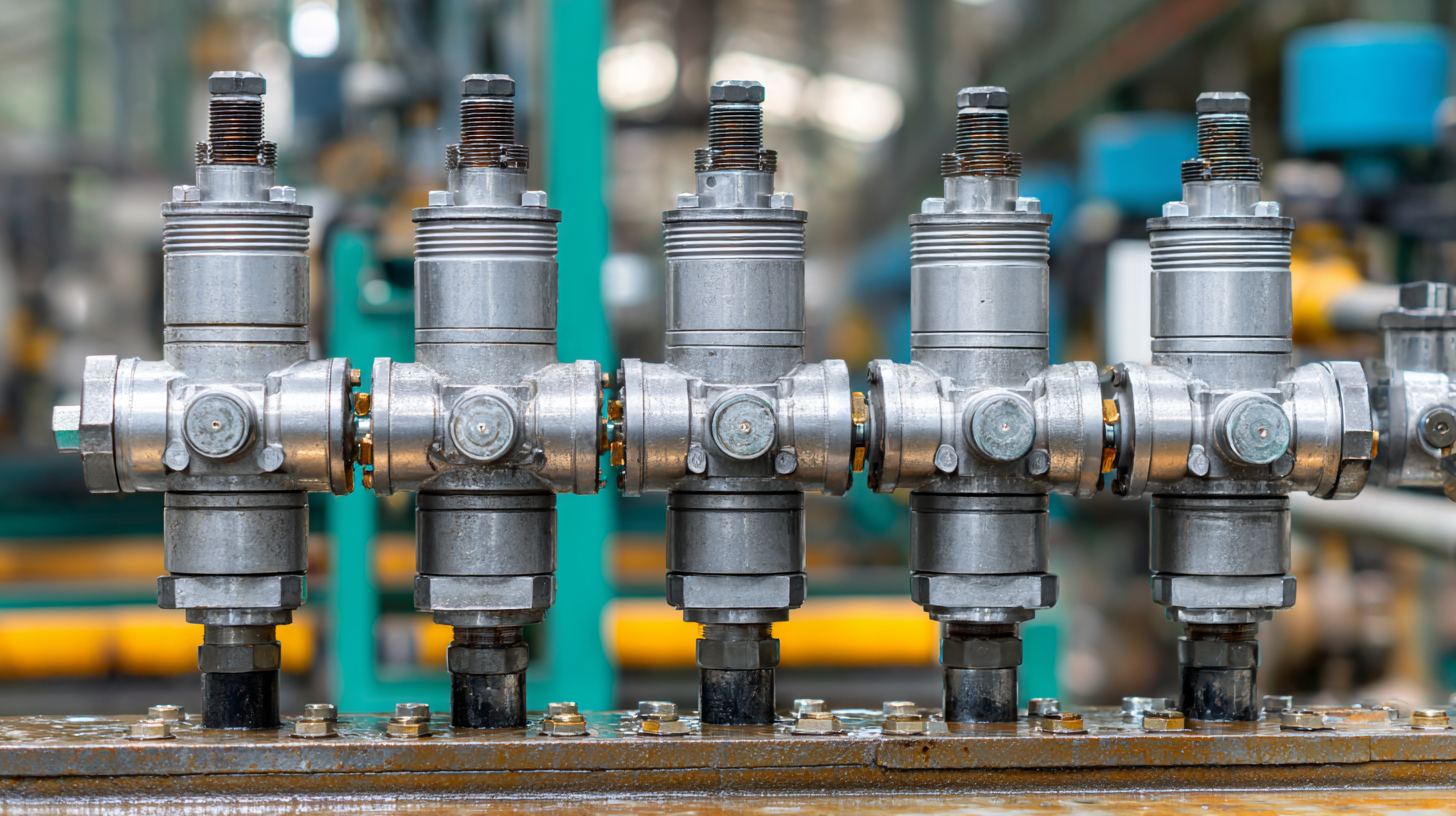

Understanding Pressure Control Valves: Types and Functions

Pressure control valves play a critical role in managing flow in various applications, ensuring that systems operate safely and efficiently. Understanding the different types of pressure control valves is essential for selecting the right one for your needs. The primary categories include pressure relief valves, pressure reducing valves, and pressure sustaining valves, each designed to handle specific functions and conditions. Pressure relief valves, for instance, are essential for preventing system overloads by releasing excess pressure, while pressure reducing valves help maintain a lower and more stable pressure downstream.

In addition to their vital functions, the design and technology behind these valves have evolved significantly. Modern pressure control valves are often equipped with advanced features that allow for precise regulation and monitoring, which is crucial in industries where even minor pressure fluctuations can lead to significant consequences. For those involved in sourcing valves, understanding these distinctions and advancements not only aids in selecting the appropriate valve type but also ensures compliance with industry standards and operational effectiveness.

Key Factors to Consider When Sourcing Pressure Control Valves

When sourcing pressure control valves, there are several key factors to consider to ensure you choose the best options for your specific applications. According to a report by MarketsandMarkets, the global pressure relief valve market is projected to reach USD 4.1 billion by 2026, driven by the increasing demand for valves in industries such as oil and gas and water treatment. Understanding these market dynamics can help you identify the right products that meet both quality and compliance standards.

Tip: Always check for industry certifications and compliance with international standards like ISO or API. This not only ensures safety but also helps mitigate risks associated with non-compliance that can lead to costly downtime.

Another critical aspect is the material and design of the valve. Valve materials can significantly impact durability and performance in high-pressure environments. A study by the American Society of Mechanical Engineers (ASME) indicates that choosing the right valve design can improve efficiency by up to 15%. Evaluate factors such as temperature resistance and corrosion properties to align with your operational needs.

Tip: Conduct a thorough analysis of your system’s pressure range and media type to select a valve that can withstand the specific conditions without compromising efficiency or safety.

Pressure Control Valves Key Factors Comparison

Top 5 Brands for Reliable Pressure Control Valves in 2023

In 2023, sourcing reliable pressure control valves is crucial for various industries, including oil and gas, water treatment, and manufacturing. According to a recent report by Grand View Research, the global pressure control valve market is expected to reach $8.7 billion by 2025, growing at a CAGR of 5.7%. This rising demand emphasizes the importance of selecting high-quality valves from reputable manufacturers. Here are the top five brands that have consistently delivered performance and reliability.

1. **Emerson** - Known for their innovative technologies, Emerson's pressure control valves offer exceptional precision and durability suited for high-pressure applications. Their Rosemount line is particularly favored for its ability to withstand challenging environments.

2. **Parker Hannifin** - With a diverse range of pressure control solutions, Parker Hannifin emphasizes efficiency and low maintenance costs. Their valves are engineered with advanced materials, ensuring longevity and reliability even under extreme conditions.

3. **Fisher** - As a subsidiary of Emerson, Fisher stands out for its robust design and accurate control features, making their valves a staple in the oil and gas sector. Their products are often recognized for their reliability and performance in critical operations.

4. **Siemens** - Siemens pressure control valves are renowned for integrating smart technology, such as digital monitoring systems, which enhance operational efficiency. Their solutions cater to multiple sectors with a focus on sustainability.

5. **Honeywell** - Honeywell's pressure control valves are designed with user-friendly features and advanced automation capabilities. They are an excellent choice for facilities looking to enhance their process control while maintaining safety standards.

Investing in valves from these trusted brands can significantly impact operational efficiency and safety, making them essential components in modern industrial systems.

Comparative Analysis of Pressure Control Valve Materials and Designs

When selecting pressure control valves, understanding the various materials and designs is crucial. According to a 2022 industry report by Grand View Research, the global market for pressure control valves is expected to reach USD 7.8 billion by 2030, driven by the increasing demand for effective pressure management in various sectors, including oil and gas and water treatment. The choice of materials, such as stainless steel, brass, and plastic, significantly impacts not only the durability but also the performance of the valve in different environmental conditions. For instance, stainless steel offers excellent corrosion resistance, making it ideal for harsh environments, while plastic valves are lightweight and suitable for less demanding applications.

Design also plays a pivotal role in the efficiency of pressure control valves. A comparative study published by the International Journal of Fluid Mechanics in 2021 highlights that bellows-sealed valves reduce leakage by up to 99% compared to traditional designs, increasing safety and reliability. Additionally, advanced designs, such as diaphragm actuated valves, provide improved response times and stability in pressure regulation. These innovations are not only enhancing operational efficiency but also contributing to significant cost savings in maintenance and energy use, underlining the importance of choosing the right valve to meet specific operational needs.

Essential Maintenance Tips for Prolonging Valve Lifespan

Maintaining pressure control valves is critical to ensuring operational efficiency and prolonging their lifespan. According to a report by the American Society of Mechanical Engineers, improper maintenance accounts for over 20% of equipment failures, which can lead to costly downtimes and repairs. Regular inspections and careful monitoring of valve performance can help identify wear and tear early, preventing emergency repairs and extending the lifespan of your valves.

One essential maintenance tip is to ensure that the valves are regularly cleaned and inspected for signs of corrosion or buildup. A study from the International Journal of Pressure Vessel and Piping highlighted that valves subjected to high levels of particulate matter or aggressive chemicals show a 40% decrease in effective lifespan. Additionally, lubricating moving parts as per manufacturer recommendations can significantly reduce friction and wear, further enhancing the durability of your pressure control valves. By implementing these maintenance strategies, organizations can maximize their investment in pressure control technology, ensuring reliability and efficiency in their operations.